Cleaning your Pleating Machine!

Bet this job rates right up there with cleaning your

sewing machine and/or serger. (And when was the last time you did that little

job?)

Never fear, cleaning your pleater takes only a few

minutes when you have everything organized.

You will need a clear space to work some Q Tips, a few

facial tissues, an old tooth brush, some sewing machine oil, the right kind of

screwdriver to fit all the screws in your pleater, and a sheet of waxed paper.

So let’s get started….

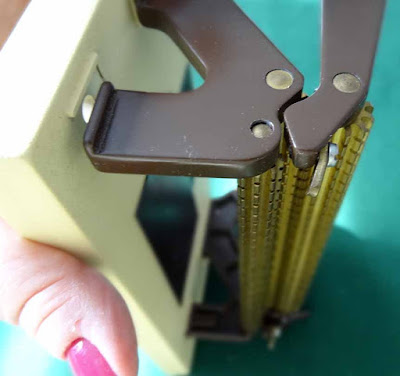

First you will need to loosen the screws that hold the toggles in place to secure the removable roller.

First you will need to loosen the screws that hold the toggles in place to secure the removable roller.

Don’t take the screws out just loosen them enough

to remove that roller. Some machines do not have a screw but a ‘pin’ that holds

the bar in place.

Lift or roll out this bar. And set aside. This is roller #1.

Next remove all the needles. Line them up or ‘nest’ them

to check for any that are bent and discard those needles in a safe manner. Set

the remaining needles aside on a tissue.

Next remove all the needles. Line them up or ‘nest’ them

to check for any that are bent and discard those needles in a safe manner. Set

the remaining needles aside on a tissue.

Now turn the machine over to remove the feet which hold

the end bracket in place. You are going to remove the ’non-handle’ end

bracket. Unscrew the feet and set them

aside also. Grasp the bars as you turn the machine upright again.

Slide the bracket and bars apart and set the bracket to

the side. Now you can remove the two removable bars. Set them aside along with

bar #1. Note that with most machines the

length of the end pieces (the part that fits into the brackets) is longer on

the last two bars so it is harder to

mix these up. Set the bars so the double spaced needle holes are at the same end. If you have a machine that is double space all the way, try to keep the bars in the same order as they were in the machine.

mix these up. Set the bars so the double spaced needle holes are at the same end. If you have a machine that is double space all the way, try to keep the bars in the same order as they were in the machine.

To clean the ends of the bars, remove any threads that

have wound round them and moisten a Q Tip with oil. Wipe the ends with the Q

Tip and then with a tissue. There will probably bel lots of black from the

brass transfer to these two. Clean the non-removable bar in a similar manner. Brush

the rollers with the toothbrush to remove any lit or other bits.

|

| See what kind of 'black' you can get and all the bits of thread |

Next clean the holes in the brackets where the rollers

sit. Swab them out with a Q Tip loaded with oil. These will probably blacken

the Q Tips as well.

Wipe the base and if necessary moisten a cloth and wipe

it down.

Tip the pleater up on the handle end to reposition roller

the three rollers starting with #3.

Replace the bracket by slipping the roller ends into

their holes. (This can be tricky but take your time.)

Grip the bracket to the base and tip wrong side up and

replace the feet. Tighten the screws that hold the feet in place.

Turn right side up. Check that all the double space needle holes all at the non-handle end and give the handle a twirl. It should move smoothly now that everything is clean and oiled.

Load the needles. Wiggle the handle slightly to settle

the needles in place then replace the last roller (the removable roller). Turn

the handle once more time then tighten the screws that hold the toggles in

place (or slip the pins in place). You might want to back off the screws a bit

from tight so the rollers turn freely.

Run a tissue through the pleater to absorb any excess oil

lest some soil your fabric.

Lastly run a piece of waxed paper through the pleater to

lubricate the needles. Be gentle removing it though lest you bend a needle.

And now your pleater is ready to get to work!!